From Data Silos to Intelligent Fabric

Rethinking Digital Foundations for Battery Labs

A comprehensive white paper on transforming fragmented lab operations into AI-native intelligent systems

When legacy systems lag, the market won’t wait.

Why the Status Quo Fails

The cost of inertia is rising — disconnected systems, delayed insights, and missed opportunities are no longer sustainable. In an era of fragmented data and shrinking timelines, battery labs must outpace not just technical complexity — but market rivals racing for dominance.

Data Silos & Fragmentation

Connectivity is not optional — it’s foundational.

Data Silos & Fragmentation

Connectivity is not optional — it’s foundational.

In battery labs, data often resides in disconnected systems, locked within individual instruments, spreadsheets, or departments. This fragmentation stalls collaboration, obscures insights, and wastes valuable test cycles. Without unification, even the most advanced tools struggle to deliver their full potential.

Curse of Dimensionality & Scale

Complexity unchecked becomes inaction.

Curse of Dimensionality & Scale

Complexity unchecked becomes inaction.

Modern battery R&D spans physics, chemistry, informatics, and engineering — across thousands of variables and test scenarios. Without structured abstraction and scale-aware orchestration, labs are overwhelmed by dimensional chaos. What begins as experimentation often devolves into paralysis.

Big Data Overload

Volume isn’t value — unless it drives decisions.

Big Data Overload

Volume isn’t value — unless it drives decisions.

More data doesn’t equal more clarity. In reality, the explosive growth of test and operational data strains infrastructure, overwhelms analysts, and delays key decisions. Labs need systems that not only collect data, but curate and contextualize it — transforming raw volume into real value.

FOMO on Critical Signals

The cost of delay isn’t just time — it’s trust.

FOMO on Critical Signals

The cost of delay isn’t just time — it’s trust.

Labs today risk missing weak signals that indicate failure modes, design flaws, or early breakthroughs. This fear of missing out (FOMO) creates reactive cultures, fire-fighting teams, and missed opportunities. Proactive intelligence — not just dashboards — is the new standard for high-performing R&D.

No Silver Bullet

The hard truth about overhyped solutions and why most digital transformation efforts fail.

Simulation does NOT meet requirements

precision therapies compared with legacy ways

could be reached in the year of

AI Can Assist, But Not Replace

Narrow acceleration ≠ systemic automation.

Recent advances in AI can accelerate tasks like material screening or anomaly detection, but full-stack intelligent lab automation remains many years away. The illusion of end-to-end replacement ignores the complexity of workflows, the nuance of context, and the gaps in infrastructure readiness.

When models lie, decisions misfire

Simulation ≠ Truth.

About 62% of respondents indicated that virtual validation tools, including physical simulation, currently do not fully ensure that battery designs meet all validation criteria/requirements. a Fundamental gaps remain in multi-scale coupling, real-time boundary conditions, and the quality of source data. Simulation today is a guide, not gospel.

MBSE Is Still a Vision

Model-Based Engineering is not yet field-ready.

NASA’s Vision 2040 roadmap makes it clear: MBSE (and its variant SBES) still faces fundamental hurdles. Multi-physics interactions, uncertainty propagation, and cross-discipline coordination are unresolved at scale. A robust model-based foundation for battery systems is still in its infancy.

EDA Took Decades — BDA Is Just Starting

Design automation isn’t born, it’s built.

EDA (Electronic Design Automation) succeeded through decades of standardization, solver evolution, and toolchain integration. Battery Data Analytics (BDA), by contrast, is still at the “big spreadsheet” stage. A true design-aware, computation-integrated BDA ecosystem will take sustained, cross-domain effort.

In-House vs Vendor: Both Face U-Turns

Lab digitalization isn’t a product — it’s a system.

In battery R&D, both in-house development and third-party platforms have hit walls. Internally built systems often underestimate cross-functional complexity, while vendor tools frequently misalign with lab realities.

he reason: digitalizing R&D isn’t just software — it’s a system engineering problem. It requires integration across physics, data science, lab operations, compliance, and strategic timing.

Without domain-depth and adaptability, both paths trigger FOMO, fragmentation, and eventual rework.

Deep Domain Expertise

Proven at Scale

Modern & Modular Architecture

AI-Powered Intelligence

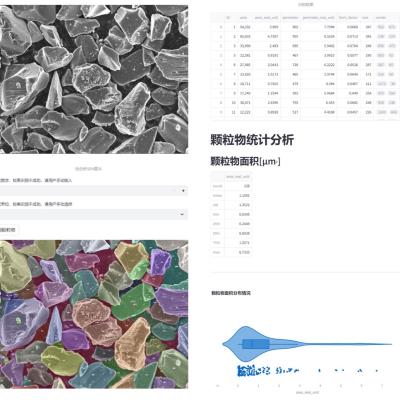

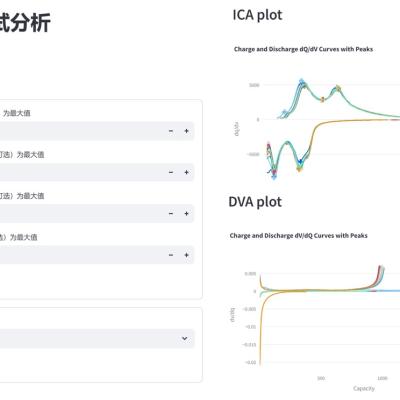

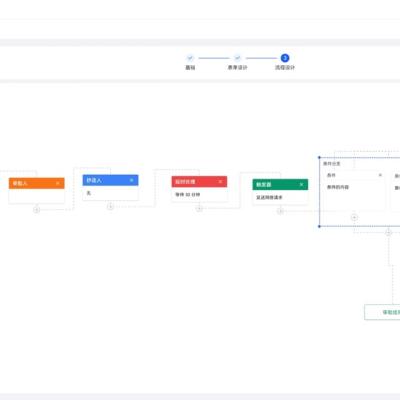

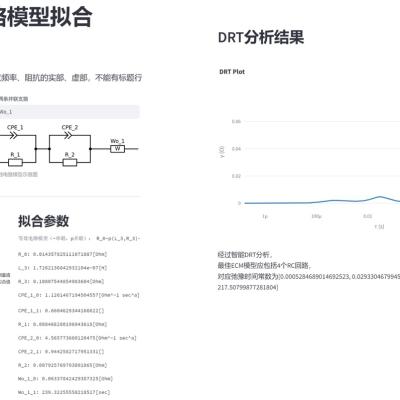

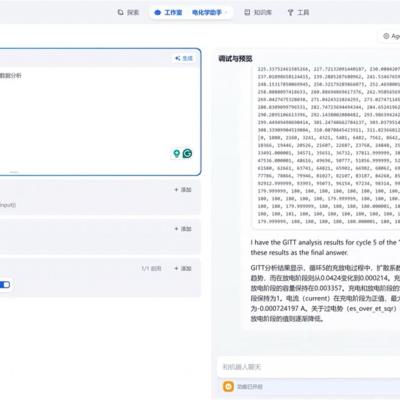

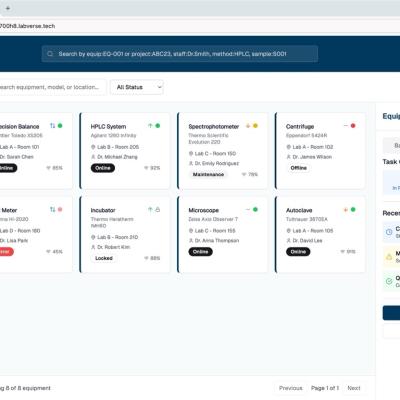

What We've Built

Real-world deployments delivering measurable ROI through intelligent automation

Automated data orchestration and intelligent routing eliminate manual bottlenecks

End-to-end system ROI through operational efficiency and accelerated insights

Join the Waitlist

Be the First to Read the Full White Paper

Our upcoming white paper, “From Data Silos to Intelligent Collaboration : The Digital Transformation Pathway for Battery R&D Labs” brings together months of insights drawn from deep client engagements, industry dialogues, and hands-on implementation across high-stakes laboratory environments.

If you’re navigating the digitalization journey in battery R&D — or simply want to avoid costly detours — we invite you to join the waitlist. You’ll gain early access to practical insights, strategic frameworks, and the lived realities that rarely make it into public conversations.